Wire Harness Assembly: Efficiency Streamlining Production

In the world of manufacturing, efficiency and consistency are paramount. Nowhere is this more evident than in wire harness assembly. As a critical component in various industries such as automotive, aerospace, and electronics, wire harnesses play a crucial role in ensuring the seamless transmission of electrical signals. To meet the demands of modern production environments, manufacturers are constantly seeking ways to streamline wire harness assembly processes for enhanced efficiency and consistency. Let’s explore how innovative approaches and technologies are transforming wire harness assembly to meet the evolving needs of industry.

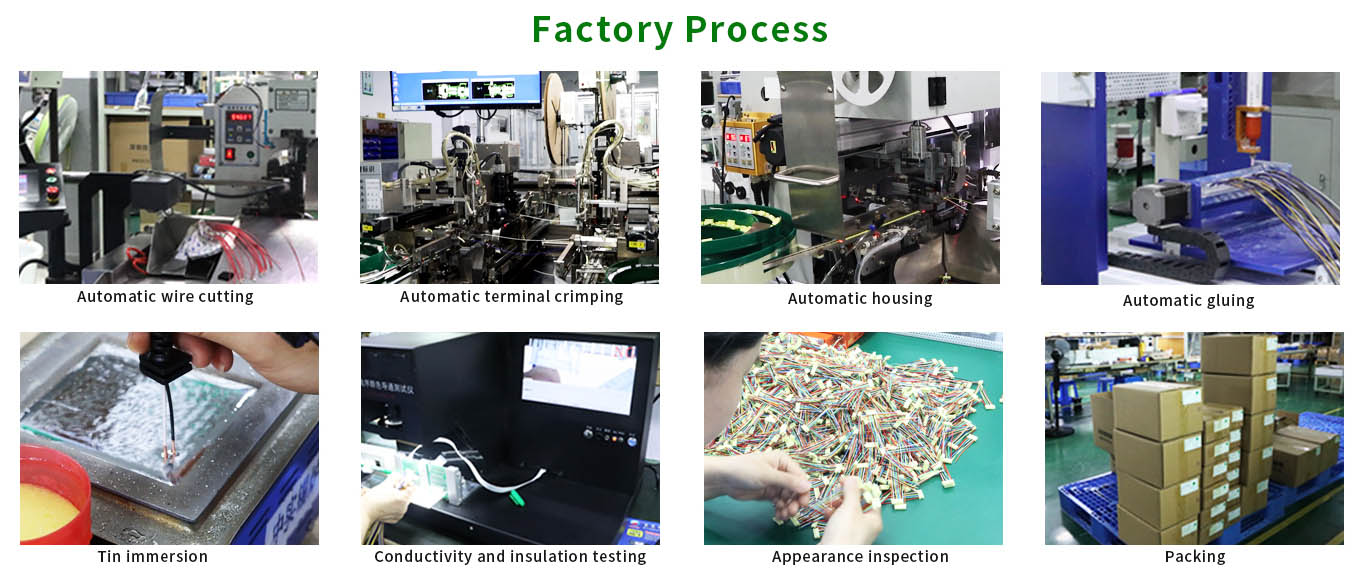

Automated Assembly Techniques:

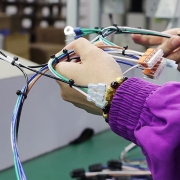

Automated assembly techniques have revolutionized wire harness production, enabling manufacturers to achieve higher throughput rates, improved accuracy, and enhanced consistency.

Advanced equipment such as automated wire cutting and stripping machines, crimping machines, and harness testing systems streamline the assembly process, reducing manual labor and minimizing errors.

Modular Design and Prefabrication:

Modular design principles and prefabrication techniques allow for the standardization of components and subassemblies, facilitating faster assembly and ensuring consistent quality across production batches.

By prefabricating subassemblies and modular components, manufacturers can reduce assembly time, minimize the risk of errors, and increase overall production efficiency.

Lean Manufacturing Principles:

Lean manufacturing principles, such as Just-In-Time (JIT) production, Kanban systems, and continuous improvement practices, are increasingly being applied to wire harness assembly operations.

By eliminating waste, optimizing workflows, and maximizing resource utilization, manufacturers can achieve greater efficiency, lower production costs, and faster turnaround times.

Quality Control and Testing:

Quality control and testing are integral parts of the wire harness assembly process, ensuring that each harness meets the highest standards of quality, reliability, and performance.

Automated testing equipment, such as continuity testers, hipot testers, and cable harness testers, verify the integrity of each harness, detecting any faults or defects before they reach the customer.

Integration of Digital Technologies:

The integration of digital technologies, such as Computer-Aided Design (CAD), Product Lifecycle Management (PLM) software, and Manufacturing Execution Systems (MES), enhances collaboration, visibility, and traceability throughout the assembly process.

Real-time monitoring and data analytics provide valuable insights into production performance, allowing manufacturers to identify areas for improvement and optimize production workflows.

In conclusion, wire harness assembly is undergoing a transformation driven by innovative technologies and manufacturing methodologies. By streamlining production processes, embracing automation, and adopting lean principles, manufacturers can achieve greater efficiency, consistency, and quality in wire harness assembly. At FPIC (Shenzhen Forman Precision Industry Co., Ltd.), we specialize in state-of-the-art wire harness assembly solutions, leveraging cutting-edge technologies and industry expertise to meet the evolving needs of our customers.

Contact us today to learn more about our wire harness assembly capabilities and discover how FPIC can support your manufacturing requirements.