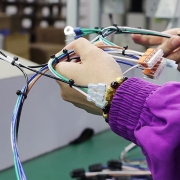

What Tests Are Required for Wiring Harness Assembly Production?

Wiring harnesses are essential components in industrial, automotive, and electronic applications, providing reliable connections for power and data transmission. To ensure their quality, durability, and safety, rigorous testing is required during production. In this article, we will explore the key tests performed on wiring harness assemblies to guarantee optimal performance in real-world applications.

1. Electrical Performance Testing

Electrical tests verify the functionality of the wiring harness, ensuring it meets design specifications and operates as expected.

✅ Continuity Test

-

Confirms that all wires are properly connected and that there are no broken circuits.

-

Ensures that current can flow seamlessly through the harness.

✅ Insulation Resistance Test

-

Measures the resistance between conductors and insulation materials to prevent leakage currents.

-

Ensures the harness can withstand electrical stress without short circuits.

✅ High-Voltage (Hipot) Test

-

Checks the dielectric strength of the insulation by applying high voltage.

-

Detects potential breakdowns or weak points in insulation.

✅ Contact Resistance Test

-

Measures the resistance at connector terminals to ensure efficient electrical conductivity.

-

Helps identify poor crimping or oxidation issues.

2. Mechanical Durability Testing

Since wiring harnesses are used in dynamic and harsh environments, mechanical tests assess their strength, flexibility, and durability.

✅ Flex & Bend Test

-

Simulates repetitive bending movements to test wire fatigue resistance.

-

Ensures the harness remains functional in applications with continuous movement, such as robotics.

✅ Tensile Strength Test

-

Applies pulling force to check the strength of wire connections and crimps.

-

Ensures connectors and terminals can withstand mechanical stress without failure.

✅ Vibration Test

-

Exposes the wiring harness to simulated vibrations that mimic real-world conditions.

-

Evaluates connector retention and wire integrity under continuous movement.

✅ Pull-Out Force Test

-

Measures the force required to disconnect terminals and connectors.

-

Ensures secure crimping and prevents accidental disconnections.

3. Environmental & Reliability Testing

Wiring harnesses must perform reliably in extreme conditions, so environmental testing is crucial.

✅ Temperature Cycling Test

-

Simulates rapid temperature changes to check the thermal expansion and contraction of materials.

-

Ensures harness functionality across hot and cold environments.

✅ Salt Spray Test

-

Exposes the harness to corrosive salt mist to assess resistance to oxidation and corrosion.

-

Crucial for automotive, marine, and outdoor applications.

✅ Waterproof & IP Rating Test

-

Tests the harness against water ingress to ensure compliance with IP67/IP68 standards.

-

Important for industrial and automotive applications exposed to moisture.

✅ Chemical Resistance Test

-

Assesses resistance to oil, fuels, and industrial chemicals that the harness may encounter.

-

Ensures long-term durability in harsh environments.

4. Functional Testing & Final Inspection

Before shipping, each wiring harness undergoes a final set of tests to validate its performance and safety.

✅ Connector Engagement & Disengagement Test

-

Evaluates how easily connectors can be inserted and removed.

-

Ensures proper locking and mating force for secure connections.

✅ Short Circuit Test

-

Detects any accidental wire contact that could cause a short circuit.

-

Ensures proper wiring assembly and insulation.

✅ End-to-End Functional Test

-

Simulates real-world operation by connecting the harness to a test system.

-

Verifies data transmission, power flow, and signal integrity.

Conclusion

Quality testing in wiring harness assembly production is essential to guarantee performance, safety, and reliability. By conducting electrical, mechanical, environmental, and functional tests, manufacturers can ensure that each harness meets industry standards and customer expectations.

At Forman, we follow strict IATF 16949, ISO 9001, ISO 14001, ISO13485 and VDA 19.1 quality control processes to deliver high-performance, tested, and certified wiring harness solutions for industrial, automotive, and automation applications.

🚀 Need a reliable and fully tested wiring harness? Contact Forman today! 🚀