Inspection and standard analysis of automobile wire harness (QC/T29106)

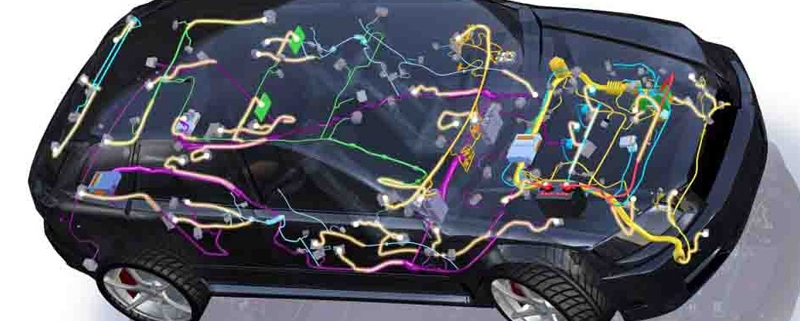

Automobile wire harness is a component that connects automotive electronic and electrical components and enables them to function. It is the main body of the automotive circuit network. It is mainly composed of copper connectors (plugs, sockets), plastic sheaths, and wires. After being connected, it is installed in a plastic sheath, and the wires are bundled with wire harnesses and wrapped with tape. The function of the wire harness in the vehicle is to transmit and exchange the power signal and data signal of the electrical system to realize the functions and requirements of the electrical system.

Automotive wiring harnesses are found in every corner of the car. There are engine wiring harnesses and cabin wiring harnesses that work in high-temperature environments, chassis wiring harnesses that work in dusty, water, and mud-immersed environments, and wiring harnesses that bridge the door and the body for a long time. Door wiring harnesses, such as power wiring harnesses that carry high-power devices for long-term full load or overload work, etc. These wiring harnesses are subjected to electrical heat loads as the vehicle works in harsh environments such as high-temperature and high-humidity southern coastal areas and severe cold northeastern regions. , the erosion of engine oil and gasoline, the baptism of bumps and vibrations and other conditions. Therefore, in order to ensure the quality of automotive wiring harnesses, attention must be paid to all aspects of design, material selection, manufacturing process, testing and assembly.

1 Analysis of test standards The current automotive wiring harness standards are mainly QC/T29106 “Technical Conditions for Automotive Low-Voltage Wire Harnesses” and the corporate standards of various enterprises. The test items generally include: inspection of crimping quality of terminals and wires or wire contacts, and waterproof performance of contacts , High and low temperature resistance and heat and humidity performance, salt spray resistance and vibration resistance of the wiring harness. If the test is carried out according to these terms, we will find that the test results are not satisfactory, such as the high and low temperature and damp heat test in Article 4.11 and 4.12 of QC/T29106. , check whether the wire harness is loosely wrapped, whether the insulation sheath is disengaged, and whether the wire conduction rate is 100%; another example is Article 4.14 salt spray test: the conduction rate of the wire harness after 48h neutral salt spray test should be 100%, no short circuit or wrong way; there is also a vibration test, which is tested according to the vibration resistance performance specified in QC/T413, but how to place the wiring harness? It is not clear in the standard, and the content of the post-vibration inspection is mainly the inspection of appearance and non-electrical performance. As mentioned above, after years of tests, it was found that these test items cannot fully verify the material, design and process of the wire harness and its auxiliary materials, and cannot fully achieve the purpose of test verification.

2 Test classification Automobile wiring harness test is divided into contact piece test and wire harness test according to structure and material; according to test category, it is divided into mechanical performance test, electrical performance test and environmental resistance test. Mechanical performance test includes vibration test; electrical performance test can be divided into short-circuit test, locked-rotor test and durability test in addition to the on-off test and contact pressure drop test of the wiring harness itself; environmental resistance test is divided into high and low temperature resistance and damp heat test, Salt spray test, waterproof, dustproof test, etc. In addition, according to the installation and working characteristics of the wiring harness itself, a deflection test is required; plastic parts such as plastic skins and corrugated pipes of the wiring harness need to be subjected to combustion tests and ozone resistance tests.

The mechanical performance test of the contact is mainly to detect the material of the terminal, the crimping quality of the terminal and the wire, such as 4.4 crimping requirements in QC/T29106, bending test, cross-section detection, tension and testing, etc. The requirements and test methods are all It is more detailed; the mechanical performance test also includes the test of insertion force and pull-out force. The test requirements and methods of this part are explained in detail in QC/T417.1, and will not be repeated here. The following mainly introduces the test items and test methods not mentioned in QC/T29106.

3 Electrical performance test The electrical performance test of the wiring harness mainly examines the design of the wiring harness, such as the selection of wire diameter, the selection of fuses, and the quality of wires and fuses. If a low-quality fuse or wire is used, the fuse cannot be disconnected immediately under the specified current, which may cause the wiring harness to overheat and catch fire. Therefore, electrical performance tests must be carried out on the relevant lines. The electrical performance test of the wiring harness is generally divided into a short-circuit test, an endurance test and a stall test of the motor wiring harness.

1) When a short circuit occurs in the wiring harness short circuit test, it is required that the fuse in the line should be blown within a certain period of time to protect the wires, connectors, etc. Connect the wiring harness to be tested and the test facility, turn on the DC regulated power supply and adjust it to the test voltage, turn on the data acquisition device and set the parameters. Close K1 and K2, observe whether the wires, connectors and fuses of the wiring harness to be tested are burned, and at the same time collect the maximum current, short-circuit time, and minimum terminal voltage when the circuit is short-circuited. During the period, if the fuse is not blown but the wire insulation is melted, the connector is melted and deformed, or the short-circuit time is greater than the specified value, it means that the design is defective or the quality of the parts is defective and needs to be rectified.

2) Wire harness durability test After the load-type wire harness has been working at full load or overload for a certain period of time, it is required that the wire harness, connectors, fuses, etc. should not be burned, and the temperature rise of the wires should not exceed the specified value. Close the switch K, set the power supply voltage, adjust the analog load resistance RL, so that the current flowing through the harness to be tested (section AB) is the test current. Use the data collector to collect the temperature of the wires, and monitor the burning of the wires, fuses, connectors, etc., if the temperature rise of the wires is lower than the required value within the specified time (such as 30min), the wires, fuse pieces (tubes), If there is no abnormality in the connectors, it can prove that the wiring harness design is basically fine.

3) Motor wiring harness stall test There are two types of motors with thermistor or fuse protection and without thermistor or fuse protection, and there are also two corresponding wiring harness stall tests. After the motor with thermistor or fuse protection is blocked for a certain period of time, the motor should be powered off for protection. The power-off protection time and recovery time can be obtained through data acquisition equipment; the motor wiring harness without protection can be tested. When the wiring harness passes through the locked-rotor current for a certain period of time (such as 15 minutes), observe whether the wires, fuses, connectors, etc. are burned, and collect the temperature of the wires and connectors through the data acquisition device to check whether the temperature rise exceeds the standard, so that Determine whether the wiring harness design is reasonable or not.

4) Wire harness deflection test Generally, the wire harness cannot be bent and twisted during installation, but the connecting wire harness between the engine compartment and the body, between the door and the body, and between the front and rear covers and the body must have bending and twisting, so this part The wire harness must undergo a deflection test to verify the durability of materials such as wires, plastic skins, and wrapping materials such as bellows and through-hole rubber sleeves. The number of deflection durability tests of each wiring harness generally varies according to the actual frequency of use. For example, the number of durability tests of the front door wiring harness is the largest, followed by the rear door; because the vehicle is operated and used in various environments, this type of wiring harness should be used in high and low temperature environments. Under the durability test. The number of deflection durability tests carried out by a certain vehicle, among which the inspection of plastic skin, bellows and other binding materials, and through-hole rubber sleeves can be done visually or with the help of a magnifying glass; while the inspection of wires can be added to the test equipment. The upper monitoring wire on-off device is used for real-time monitoring.

The specific operation method is to connect the wiring harness to be tested with the wiring harness or electrical box that is docked with it, fix it on the vibration table according to the actual loading state, connect the wires in the wiring harness to form a loop, and connect a 120Ω/2W The resistor and the DC power supply are connected in series, and the power supply voltage is adjusted so that the loop current is 100mA. During the whole vibration test period, use the data acquisition instrument to collect and record the current flowing through the resistor, and analyze whether it meets the acceptance requirements (acceptance requirements: the time for the current flowing through the resistor ≤ 95mA ≤ 1μs). The acceptance standard can also be based on the actual use Determine for yourself. In addition to the selection of vibration frequency and acceleration in accordance with the requirements of QC/T413, the road spectrum of the relevant wiring harness part can also be collected on some typical road conditions, and then through iteration and processing, the vibration table is loaded onto the wiring harness to be tested to complete the vibration test.

In short, the automotive wiring harness is a combination of wires, terminals, plastic skins, insulating wrappings, electrical boxes, fuses, etc., so the wiring harness test must verify the quality of each raw material, check the design, manufacturing process, etc. in various working environments The reliability ensures the safety of the vehicle.