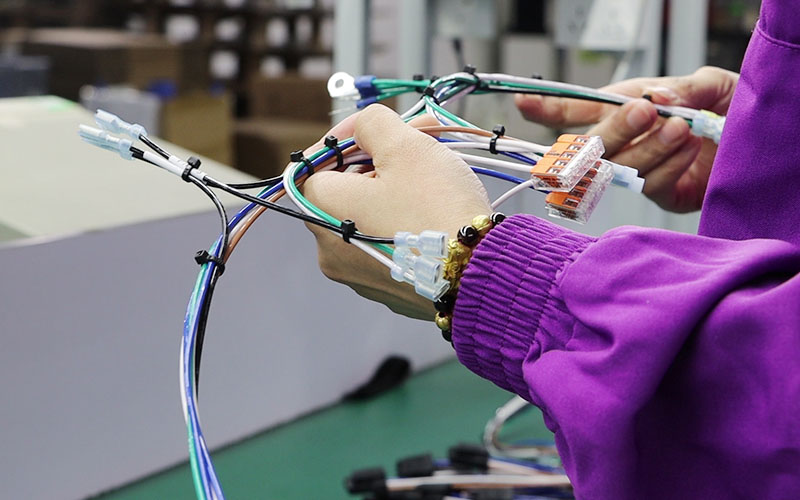

How to Troubleshoot Common Issues in Wiring Harnesses?

Wiring harnesses are essential in modern electrical systems, ensuring proper power distribution, signal transmission, and system functionality. However, like any complex assembly, they can face issues over time due to environmental factors, mechanical stress, or manufacturing defects. Identifying and resolving these problems is critical to maintaining the reliability of any device or system they support.

In this article, we explore how to troubleshoot the most common issues in wiring harnesses and how FPIC’s quality assurance and advanced testing practices help mitigate them before they reach the customer.

Common Wiring Harness Issues and How to Fix Them

1. Intermittent Connections

-

Symptoms: Power flickering, signal drops, inconsistent performance.

-

Cause: Loose terminals, poor crimping, vibration damage.

-

Troubleshooting Tips:

-

Perform a continuity test using a multimeter.

-

Visually inspect crimp areas for looseness.

-

Re-crimp or replace damaged terminals if needed.

-

2. Short Circuits

-

Symptoms: Blown fuses, overheating, complete circuit failure.

-

Cause: Pinched wires, insulation breakdown, incorrect routing.

-

Troubleshooting Tips:

-

Use a short circuit tester or insulation resistance tester.

-

Inspect harness areas passing through tight bends or high-friction zones.

-

Apply protective tubing and re-route wires to prevent recurrence.

-

3. Connector Failures

-

Symptoms: Loss of communication or power at specific terminals.

-

Cause: Corrosion, bent pins, improper mating, low-quality connectors.

-

Troubleshooting Tips:

-

Clean contacts with electronic contact cleaner.

-

Replace worn connectors with higher-grade components.

-

Use IP-rated connectors in harsh environments.

-

4. Wire Breaks and Fractures

-

Symptoms: Total failure in certain functions or no power delivery.

-

Cause: Over-flexing, manufacturing defects, or thermal cycling.

-

Troubleshooting Tips:

-

Perform a wiggle test while monitoring continuity.

-

Visually check for cracked or discolored insulation.

-

Use high-flex or TPE-insulated wires in mobile applications.

-

5. Noise and Signal Interference

-

Symptoms: Data corruption, EMI issues, sensor errors.

-

Cause: Poor shielding, ground loops, lack of twisted pairs.

-

Troubleshooting Tips:

-

Verify grounding quality.

-

Use shielded cables with proper drain wire terminations.

-

Ensure separation between power and signal lines.

-

FPIC’s Commitment to Wiring Harness Quality

At FPIC, we take reliability seriously. Our wiring harnesses are tested under strict standards before leaving the production floor. We support global compliance and carry certifications such as ISO 9001, ISO 14001, ISO 13485, UL, TUV, and IATF 16949, ensuring our products meet industrial, medical, and automotive application requirements.

We also implement:

-

VDA 19.1 cleanroom standards for high-purity applications.

-

Automated testing for continuity, shorts, and pin mapping.

-

Material traceability and lifecycle monitoring.

Partner with FPIC for Reliable Wiring Harness Solutions

Preventing wiring harness problems starts with choosing a trustworthy manufacturing partner. Whether you’re in automotive, energy storage, industrial automation, or medical sectors, FPIC provides custom, high-performance wiring harness assemblies that stand the test of time.

📩 Contact us today at info@sz-fpi.com or visit www.sz-fpi.com to discuss your project needs.