What are Wiring Harnesses Used for?

In the world of electrical systems and connectivity, wiring harnesses play a crucial role. These intricate assemblies of wires, connectors, and terminals are the unsung heroes behind the seamless operation of countless devices and machines. From automobiles to industrial equipment, wiring harnesses serve as the nervous system, transmitting power and signals throughout complex systems. Let’s delve into the multifaceted applications and importance of wiring harnesses in various industries.

The Fundamental Purpose of Wiring Harnesses

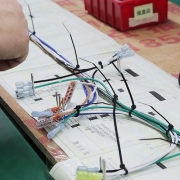

At its core, a wiring harness is designed to streamline electrical connections within a system. By bundling individual wires and cables together, it creates an organized and efficient network for power distribution and signal transmission. This consolidation offers numerous benefits:

- Simplified Installation: Wiring harnesses allow for quicker and more straightforward installation processes, reducing assembly time and labor costs.

- Enhanced Organization: By grouping wires together, harnesses minimize clutter and improve the overall layout of electrical systems.

- Increased Reliability: Properly designed harnesses protect wires from environmental factors, reducing the risk of shorts, disconnections, and other electrical failures.

- Improved Maintenance: When repairs or upgrades are necessary, wiring harnesses make it easier to locate and access specific connections.

The versatility of wiring harnesses makes them indispensable in a wide range of applications, from automotive systems to sophisticated medical equipment.

Applications Across Industries

Wiring harnesses find their way into numerous sectors, each with its unique requirements and challenges. Let’s explore some of the primary industries that rely heavily on these electrical assemblies:

Automotive Industry

In the automotive sector, wiring harnesses are the lifeline of modern vehicles. They connect various electronic components, ensuring the proper functioning of everything from basic lighting systems to advanced driver assistance features. Some key applications include:

- Engine Management Systems: Harnesses link sensors, actuators, and control modules for optimal engine performance.

- Infotainment Systems: They facilitate the integration of audio, navigation, and connectivity features.

- Safety Systems: Wiring harnesses are crucial for airbag deployment, anti-lock braking systems, and traction control.

- Lighting and Signaling: They enable the operation of headlights, taillights, turn signals, and interior lighting.

As vehicles become increasingly electrified and autonomous, the complexity and importance of wiring harnesses in automotive applications continue to grow.

Industrial and Manufacturing

In industrial settings, wiring harnesses play a vital role in powering and controlling machinery and equipment. Their applications include:

- Robotics and Automation: Harnesses enable precise control and communication in robotic systems and automated production lines.

- Control Panels: They organize and simplify connections within industrial control panels, enhancing reliability and ease of maintenance.

- Heavy Machinery: Wiring harnesseswithstand harsh conditions in construction and mining equipment, ensuring reliable operation.

- HVAC Systems: They facilitate the integration of sensors, controls, and power distribution in heating, ventilation, and air conditioning systems.

The durability and customization options of wiring harnesses make them ideal for the diverse needs of industrial applications.

Aerospace and Defense

In the aerospace and defense sectors, wiring harnesses must meet stringent reliability and performance standards. Their applications include:

- Aircraft Systems: Harnesses connect avionics, flight control systems, and communications equipment.

- Satellite Technology: They ensure reliable power and data transmission in space-based systems.

- Military Vehicles: Wiring harnesses support advanced electronics and communication systems in military ground vehicles.

- Radar and Surveillance Equipment: They enable the integration of complex sensor and data processing systems.

The high-stakes nature of aerospace and defense applications demands wiring harnesses of exceptional quality and reliability.

Medical Equipment

In the medical field, wiring harnesses are essential components of various diagnostic and treatment devices. Applications include:

- Imaging Systems: Harnesses support the intricate connections in MRI, CT, and X-ray machines.

- Patient Monitoring Devices: They enable the accurate transmission of vital signs and other patient data.

- Surgical Equipment: Wiring harnessespower and control precision instruments used in operating rooms.

- Wearable Medical Devices: They facilitate the integration of sensors and communication modules in portable health monitoring devices.

The Future of Wiring Harnesses

As technology continues to advance, the role of wiring harnesses evolves alongside it. Several trends are shaping the future of these essential components:

- Weight Reduction: In industries like automotive and aerospace, there’s a growing focus on lightweight materials and designs to improve fuel efficiency.

- High-Speed Data Transmission: With the rise of connected devices and autonomous systems, wiring harnesses are being optimized for faster data transfer rates.

- Modular Design: Manufacturers are moving towards more modular harness designs, allowing for easier customization and maintenance.

- Integration of Smart Technologies: Some wiring harnesses now incorporate sensors and diagnostic capabilities, enabling predictive maintenance and improved reliability.

- Sustainability: There’s an increasing emphasis on using recyclable materials and designing harnesses for easier end-of-life recycling.

Conclusion

Wiring harnesses are the unsung heroes of modern technology, providing the vital connections that power our world. From the cars we drive to the medical equipment that saves lives, these intricate assemblies of wires and connectors play an indispensable role. As technology continues to advance, the importance and sophistication of wiring harnesses will only grow.

At Shenzhen Forman Precision Industry Co., Ltd., we understand the critical nature of wiring harnesses in various industries. With over 21 years of experience in connector manufacturing and a decade of expertise in wire harness production, we’re committed to delivering high-quality, customized solutions that meet the evolving needs of our customers. Our state-of-the-art facilities, rigorous quality control processes, and dedicated team ensure that we can tackle even the most challenging wiring harness requirements.

Whether you’re in automotive, industrial, medical, or any other sector requiring reliable electrical connections, we’re here to support your needs. For more information about our wiring harness solutions or to discuss your specific requirements, please don’t hesitate to contact us at info@sz-fpi.com. Let us help you power your innovations with precision-engineered wiring harnesses tailored to your unique specifications.

References

- Amin, M., & Mahmud, F. (2019). Design and development of vehicle wiring harness. International Journal of Automotive Engineering and Technologies, 8(3), 107-115.

- Bentley, J. P. (2020). Principles of measurement systems. Pearson Education Limited.

- Godwin, A. R. (2018). Automotive electrical and engine performance. Jones & Bartlett Learning.

- Ribbens, W. B. (2017). Understanding automotive electronics: An engineering perspective. Butterworth-Heinemann.

- Zhang, J., & Niu, X. (2020). Research on key technology of automobile wiring harness design. Journal of Physics: Conference Series, 1627(1), 012048.