Top 10 Advantages of Using Medical Wiring Harnesses

Top 10 Advantages of Using Medical Wiring Harnesses in Healthcare Applications

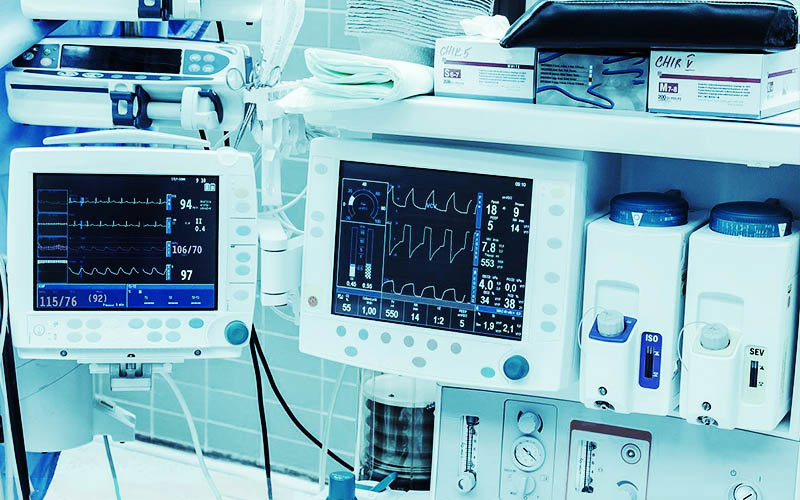

In the fast-paced world of healthcare, efficiency, precision, and reliability are non-negotiable. At the core of many medical devices lies a vital component: the medical wiring harness. Designed to streamline electrical systems and improve device performance, medical wiring harnesses have become indispensable in healthcare technology. But what makes these components so crucial? Let’s explore the top 10 advantages of using medical wiring harnesses in healthcare applications.

1. Improved Organization and Compact Design

Medical wiring harnesses combine multiple wires, cables, and connectors into a single assembly. This not only minimizes clutter but also ensures a cleaner, more organized internal structure for medical devices. A streamlined design is particularly important for compact equipment, such as wearable medical devices or portable diagnostic tools.

2. Enhanced Durability and Longevity

Built using medical-grade materials like PVC, silicone, or thermoplastic elastomers, medical wiring harnesses are engineered to withstand harsh environments. Whether it’s frequent sterilization, exposure to chemicals, or extreme temperatures, these harnesses are designed to last, ensuring devices remain reliable over time.

3. High Precision and Signal Integrity

In healthcare applications, precision is paramount. Medical wiring harnesses ensure accurate signal transmission and power delivery, which are critical for devices like ECG monitors, imaging equipment, and surgical tools. Advanced shielding and insulation further prevent electromagnetic interference (EMI), enhancing signal integrity.

4. Compliance with Industry Standards

Medical wiring harnesses are manufactured to meet stringent global standards, including ISO13485 for medical device quality management systems. Compliance ensures that the harnesses are safe, reliable, and suitable for critical healthcare applications, giving manufacturers and end-users peace of mind.

5. Easy Customization for Diverse Applications

From diagnostic machines to surgical tools, each healthcare device has unique wiring requirements. Medical wiring harnesses can be fully customized to meet specific needs, including connector types, wire lengths, and insulation materials. This flexibility allows for seamless integration into various medical systems.

6. Space and Weight Efficiency

By bundling multiple cables into a single assembly, medical wiring harnesses save space and reduce the overall weight of the device. This is particularly beneficial in compact medical devices, such as handheld ultrasound scanners or portable infusion pumps, where every gram and millimeter counts.

7. Faster Installation and Maintenance

Pre-assembled medical wiring harnesses simplify the manufacturing and maintenance processes. With all components organized and pre-tested, installation becomes faster and more efficient, reducing production timelines. Maintenance is also easier, as each harness is designed for quick identification and replacement.

8. Reduced Risk of Malfunctions

By eliminating loose or tangled wires, medical wiring harnesses significantly reduce the risk of electrical faults or malfunctions. This ensures the uninterrupted operation of critical medical devices, which can be life-saving in high-pressure environments like operating rooms or ICUs.

9. Cost Savings in Production

While the initial cost of a medical wiring harness might seem higher than individual wires, it offers long-term cost savings. Pre-assembled harnesses reduce labor costs, speed up manufacturing, and minimize errors during production, leading to greater efficiency and profitability.

10. Support for Advanced Technologies

As healthcare technology advances, so do the demands on wiring solutions. Medical wiring harnesses are designed to support cutting-edge medical technologies, including robotic surgical systems, AI-powered diagnostic tools, and IoT-enabled devices. Their adaptability ensures compatibility with the latest innovations in the industry.

Why Choose FPIC for Your Medical Wiring Harness Needs?

FPIC is a trusted manufacturer of high-quality medical wiring harnesses and cable assemblies. With ISO13485 certification and decades of experience, we deliver reliable, durable, and customizable wiring solutions for healthcare applications.

Our expertise includes:

- Medical-grade materials for superior durability and safety.

- Advanced designs to support compact, lightweight, and efficient systems.

- Commitment to zero defects and 100% delivery success.

FPIC works closely with medical device manufacturers to create custom wiring solutions that meet the highest industry standards, ensuring optimal performance and reliability for life-saving devices.

Conclusion

The advantages of using medical wiring harnesses in healthcare applications are clear: from enhanced reliability and precision to reduced costs and faster production. As medical technology continues to evolve, wiring harnesses remain at the forefront, ensuring the seamless operation of critical devices.

If you’re seeking a dependable partner for your medical wiring harnesses, FPIC is here to help. Contact us today to learn more about how our solutions can benefit your healthcare applications and elevate your devices to the next level.

References

- Medical Equipment Cabling Systems. Anderson, L., Medical Technology Insights, 2021, pp. 56–60.

- ISO13485: Quality Management for Medical Devices. International Organization for Standardization (ISO), 2023.

- The Importance of Reliable Wiring in Healthcare Devices. Roberts, M., Journal of Medical Engineering, 2022.