The Essential Guide to Wire Harness Manufacturing: From Concept to Completion

In the intricate world of modern manufacturing, wiring harnesses serve as the unsung heroes that power a wide array of industries, from automotive and aerospace to healthcare and consumer electronics. These complex assemblies of wires, connectors, and terminals play a critical role in ensuring the seamless operation of machinery, vehicles, and electronic devices. But how exactly are wiring harnesses manufactured, from concept to completion? Let’s delve into the essential guide to wiring harness manufacturing:

Conceptualization and Design Phase:

The journey begins with the conceptualization of the wiring harness, where engineers and designers collaborate to define the specifications, requirements, and functionality of the harness.

Detailed design drawings and schematics are created, outlining the layout, wire routing, connector types, and other critical parameters of the harness.

Advanced computer-aided design (CAD) software is often employed to model the harness and simulate its performance under various conditions, ensuring accuracy and efficiency in the design process.

Material Selection and Procurement:

Once the design is finalized, the next step involves selecting the appropriate materials and components for the wiring harness. This includes wires, connectors, terminals, insulating materials, and protective sheathing.

High-quality materials that meet industry standards and regulatory requirements are sourced from trusted suppliers to ensure reliability, durability, and performance of the harness.

Precision Manufacturing and Assembly:

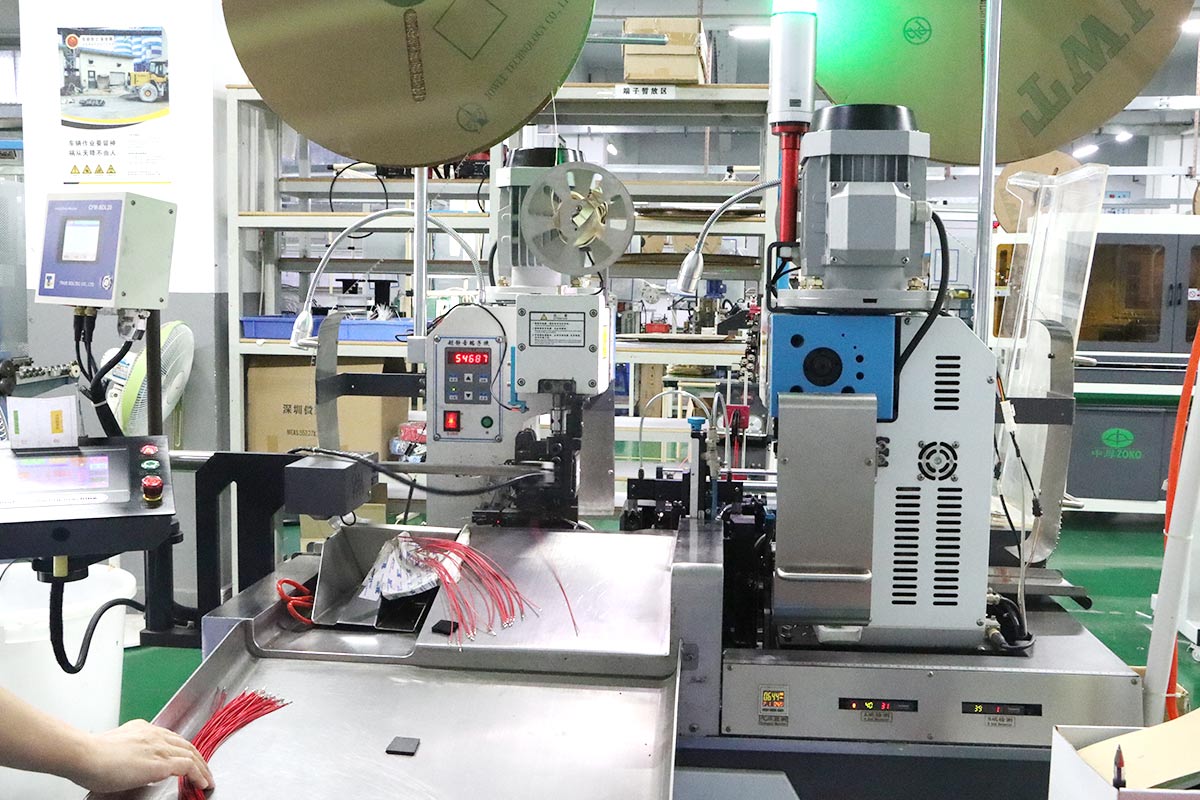

With materials in hand, the manufacturing process commences with precision and attention to detail. Automated machinery and specialized equipment are utilized to strip, cut, crimp, and solder wires to exact specifications.

Skilled technicians carefully assemble the harness components according to the design drawings, following strict quality control procedures to ensure accuracy and consistency.

Harnesses may undergo testing and inspection at various stages of the assembly process to detect any defects or discrepancies and ensure compliance with quality standards.

Testing and Quality Assurance:

Comprehensive testing and quality assurance procedures are integral to the manufacturing process to verify the performance, functionality, and safety of the wiring harness.

Electrical testing, continuity testing, insulation resistance testing, and other tests are conducted to validate the integrity of the harness and identify any potential issues.

Harnesses may also undergo environmental testing, such as thermal cycling, vibration testing, and moisture resistance testing, to assess their reliability and durability under real-world conditions.

Packaging and Shipping:

Once the harnesses have passed rigorous testing and quality checks, they are carefully packaged to protect them during transit and storage.

Proper labeling and documentation are provided to ensure traceability and facilitate installation and integration into the final products.

Harnesses are shipped to customers or assembly facilities, where they play a vital role in powering a diverse range of applications, from vehicles and machinery to medical devices and electronic systems.

In conclusion, wiring harness manufacturing is a highly intricate and precise process that requires expertise, precision, and attention to detail at every stage. FPIC (Shenzhen Forman Precision Industry Co., Ltd.) specializes in the design and manufacturing of high-quality wiring harnesses tailored to the unique needs of diverse industries. With a commitment to excellence and customer satisfaction, FPIC delivers reliable, innovative, and cost-effective harness solutions that power innovation and drive success in the global marketplace.

For inquiries about our wiring harness manufacturing capabilities or to discuss your specific requirements, please contact us at info@sz-fpi.com. Let FPIC be your trusted partner in bringing your wiring harness concepts to fruition and powering your success in the competitive landscape of modern manufacturing!