Key Considerations in Wiring Harness Assembly

Introduction

Wiring harness assembly is a critical process in automotive, industrial, and new energy applications, requiring high precision, quality control, and compliance with international standards. At Shenzhen Forman Precision Industry Co., LTD (FPIC), we take pride in our advanced production process, strict quality management, and industry-leading cleanliness standards. Our assembly process meets the stringent VDA 19.1 (ISO 16232-10) cleanliness requirements, ensuring high-reliability harnesses for automotive and high-performance industries.

In this article, we will explore the key considerations in wiring harness assembly, focusing on process control, technical requirements, and best practices from both production management and technical engineering perspectives.

1. Process Control & Cleanliness Standards in Wiring Harness Assembly

1.1. Meeting VDA 19.1 (ISO 16232-10) Cleanliness Standards

One of the most crucial aspects of wiring harness assembly is ensuring a contaminant-free production environment. At FPIC, we strictly follow VDA 19.1 standards, which regulate technical cleanliness in automotive components, ensuring our harnesses are free from particulate contamination that could affect electrical performance.

How We Achieve High Cleanliness:

✅ Controlled Assembly Areas – Dust-free production workshops with filtered air systems.

✅ Component Cleaning & Handling – Regular degreasing, ultrasonic cleaning, and particle analysis to prevent contamination.

✅ Automated Cutting & Crimping – Minimizing manual contact to reduce dust and debris accumulation.

✅ Workstation Cleanliness – Strict 5S management principles ensuring an organized, contamination-free workspace.

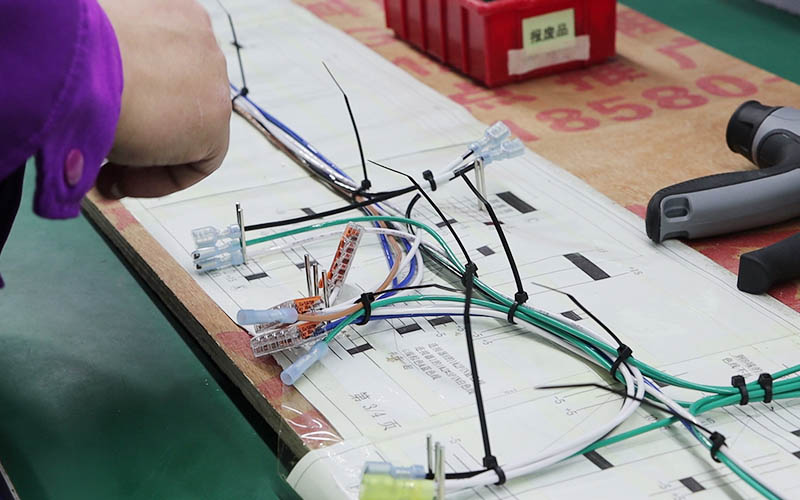

1.2. Standardized Process Flow for High-Quality Assembly

To maintain high precision and reliability, FPIC implements a well-defined wiring harness assembly workflow:

🔹 Wire Cutting & Stripping – Automated machines ensure precision length control and clean cuts.

🔹 Crimping & Terminal Connection – High-precision crimping tools ensure consistent electrical conductivity.

🔹 Harness Routing & Layout – Following design blueprints to ensure correct placement and strain relief.

🔹 Connector & Housing Assembly – Ensuring secure connections to prevent loose contacts or signal loss.

🔹 Electrical Testing & Quality Inspection – 100% continuity testing, insulation resistance checks, and high-voltage testing.

🔹 Packaging & Final Cleanliness Inspection – Adhering to VDA 19.1 standards before shipment.

2. Technical Considerations for Wiring Harness Assembly

2.1. Ensuring Strong Crimping & Electrical Connections

The crimping process is one of the most crucial factors affecting the quality of a wiring harness. Poor crimping can lead to increased resistance, overheating, or electrical failure.

Key Considerations in Crimping:

🔹 Consistent Crimp Height & Width – FPIC uses automated crimp force monitoring (CFM) systems to detect defects.

🔹 Correct Wire Gauge & Terminal Compatibility – Avoiding over-crimping or under-crimping, which could weaken conductivity.

🔹 Pull-Force Testing – Ensuring strong mechanical retention to withstand vibrations and mechanical stress.

2.2. Proper Routing & Strain Relief for Longevity

Correct routing and strain relief prevent wire damage, short circuits, and long-term degradation. FPIC engineers carefully design each harness layout to:

✅ Avoid sharp bends or excessive tension that may cause breakage.

✅ Ensure even wire distribution to prevent electrical interference.

✅ Use heat-resistant and flame-retardant materials to enhance safety.

2.3. Waterproofing & Environmental Protection (IP67/IP68 Standards)

Many wiring harnesses are exposed to harsh environments, including moisture, dust, and extreme temperatures. FPIC ensures IP67/IP68 protection for harnesses used in automotive, outdoor, and industrial applications.

Protective Measures Include:

🔹 Sealed connectors & gaskets to prevent water ingress.

🔹 Heat-shrink tubing & overmolding for enhanced insulation.

🔹 Corrosion-resistant materials ensuring long-term reliability.

3. FPIC’s Strong Quality Management System (QMS) & Certifications

At FPIC, our wiring harness assembly process is backed by a robust quality management system, ensuring compliance with international industry standards:

✅ IATF 16949 – Automotive quality management system.

✅ ISO 9001 – General quality control certification.

✅ ISO 14001 – Environmental management compliance.

✅ VDA 19.1 (ISO 16232-10) – Ensuring cleanliness standards in electrical components.

✅ 100% Electrical Testing – Each harness undergoes high-voltage, continuity, and insulation resistance testing before shipment.

Why This Matters:

By adhering to these strict quality controls, FPIC guarantees that our customers receive high-performance wiring harnesses with maximum reliability and durability.

4. Why Choose FPIC for Wiring Harness Assembly?

At FPIC, we take pride in our advanced manufacturing process, strict cleanliness control, and high-quality standards. Here’s why our customers trust us:

✔️ Industry-Leading Cleanliness Control – Fully compliant with VDA 19.1 & ISO 16232-10 standards.

✔️ Automated & Precision Manufacturing – High-speed automation minimizes errors and ensures repeatable quality.

✔️ Customizable Solutions – Tailored harness designs to meet specific automotive, industrial, and energy storage applications.

✔️ Global Supply Chain Support – Reliable mass production capabilities with on-time delivery.

🚀 Looking for a high-quality wiring harness assembly partner? FPIC is your trusted manufacturer! 🚀

Conclusion

Wiring harness assembly requires expertise, precision, and rigorous quality control to ensure optimal performance and reliability. At FPIC, our commitment to process excellence, cleanliness standards (VDA 19.1), and international certifications (IATF 16949, ISO 9001, ISO 14001) ensures that our customers receive high-quality wiring harness solutions for automotive, industrial, and energy applications.

🔹 Want to learn more about our wiring harness solutions? Contact FPIC today!

📩 Email us at: info@sz-fpi.com

🌐 Contact Us: [Send Inquiry]