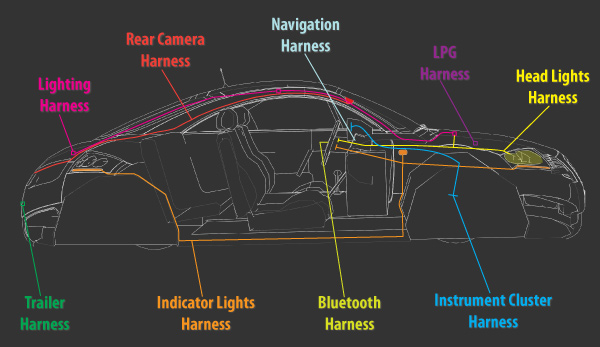

Le faisceau de câbles principal du wtrouLe véhicule est généralement divisé en moteur (allumage, EFI, production d'énergie, démarrage), instrumentation, éclairage, climatisation, appareils électriques auxiliaires et autres pièces, avec faisceau de câbles principal et faisceau de câbles de dérivation. Le faisceau de câbles principal de l'ensemble du véhicule prend souvent le tableau de bord comme partie centrale et s'étend vers l'avant et vers l'arrière. En raison de la relation de longueur ou de la commodité d'assemblage, le faisceau de câbles de certaines voitures est divisé en faisceau de câbles avant (y compris l'instrument, le moteur, l'ensemble de phares, le climatiseur, la batterie), faisceau de câbles arrière (ensemble de feux arrière, éclairage de plaque d'immatriculation, éclairage de coffre), faisceau de câblage de toit (portes, plafonniers, haut-parleurs audio), etc.

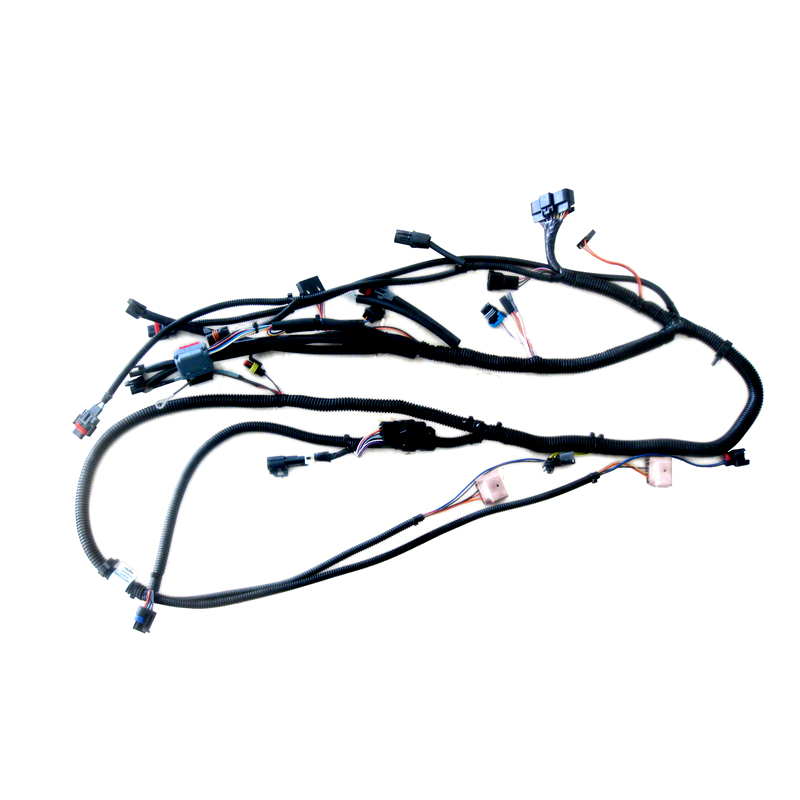

Faisceau de câbles automobile

Service OEM/ODM

Le faisceau de câbles automobile a trèsexigences strictes sur les matériaux :

1. La température ambiante autour du moteur est élevée et il existe de nombreux gaz et liquides corrosifs. Par conséquent, les fils du faisceau de câbles du moteur doivent utiliser des fils résistants aux hautes températures, à l'huile, aux vibrations et aux frottements.

2. Les fils de la transmission automatique utilisent des fils qui résistent à l'huile hydraulique, aux hautes températures et qui ont une bonne stabilité thermique.

3. Les fils du faisceau de câbles sur le couvercle du coffre à bagages doivent conserver leur élasticité à basse température, de sorte que des fils élastiques froids doivent être sélectionnés pour un fonctionnement normal.

4. Les capteurs de signal faible doivent utiliser des fils blindés.

5. L'assemblage du faisceau de câbles ABS utilise une résistance à haute température de 150-200 ° C, une couche d'isolation protectrice externe dure, une résistance à l'usure et le noyau du fil est combiné en un fil toronné.

6. Les fils utilisés pour les lignes électriques telles que les fils de sortie de l'alternateur de démarrage et les fils de batterie sont des fils spéciaux qui peuvent résister à des courants importants, ont une bonne performance de dissipation thermique de la couche d'isolation et réduisent la tension.

les industries&Solutions

En tant que partenaire stratégique, FPIC propose des solutions innovantes adaptées à vos exigences en matière de faisceaux de câbles et de câbles. Nous fournissons des solutions d'interconnexion et de fabrication fiables pour diverses applications telles que les nouvelles énergies, les équipements industriels, les équipements médicaux, les automobiles, les véhicules électriques, etc.